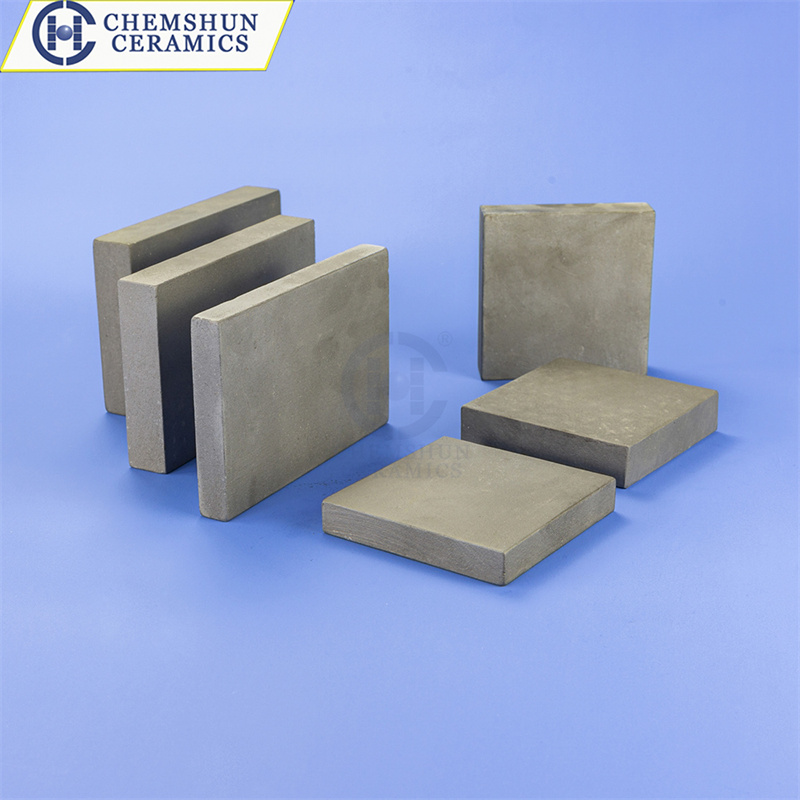

Rection Bonded Silicon Carbide Tile

Melemo ea Reaction Bonded Silicon Carbide

1) Boima bo tlaase.

2) Ho hanyetsa kutu.

3) Apara khanyetso.

4) Ho hanyetsa oxidation.

5) Ho hanyetsa abrasion.

6) Ho hanyetsa mocheso o motle oa mocheso (ka lebaka la coefficient e tlase ea ho atolosa mocheso le conductivity e phahameng ea mocheso).

7) Excellent Matla ka mocheso phahameng.

8) Taolo e ntle ea libopeho tse rarahaneng.

Apara lihlahisoa tse hanyetsanang: Silicon carbide plate, Silicon carbide setene, Pipe line, Pipe Cone, leholiotsoana, joalo-joalo.

Thepa ea ka tlung: Plate, Beam, Roller, Burner Nozzle, Round Beam, square beam, sekoti sa lesoba.Crucible, Sagger, joalo-joalo.

Tse ling: Li-nozzles tsa desulfurization

Tšebeliso ea Reaction Bonded Silicon Carbide:

Reaction bonded silicon carbide e ipakile e le khetho e ntle ka ho fetesisa ea lisebelisoa bakeng sa lisebelisoa tse kang liphaephe, Nozzles, likhoele tsa taolo ea phallo le likarolo tse kholo tsa ho roala merafong hammoho le liindasteri tse ling.

Parameter e kholo

| Thepa | Diyuniti | SiSiC/RBSIC |

| Boima ba bongata (SiC) | V01% | ≥85 |

| Boima ba bongata | g/cm3 | 3.01 |

| porosity e bonahalang | % | <0.1 |

| Modulus ea ho phatloha ho 20 ℃ | Mpa | 250 |

| Modulus ea ho phatloha ho 1200 ℃ | Mpa | 280 |

| Modulus ea elasticity ho 20 ℃ | GPA | 330 |

| Ho robeha ho thata | Mpa*m1/2 | 3.3 |

| Thermal Conductivity ho 1200 ℃ | wm-1.k-1 | 45 |

| Katoloso ea mocheso ho 1200 ℃ | a×10-6/℃ | 4.5 |

| Ho hanyetsa mocheso oa mocheso ho 1200 ℃ | Hantle haholo | |

| Coefficient ea mahlaseli a mocheso | <0.9 | |

| Max.mocheso o sebetsang | ℃ | 1350 |

Boholo

e ka etsoa ho latela litlhoko tsa bareki.

Tshebeletso

Re amohela litaelo tsa tloaelo.

Haeba u batla ho tseba haholoanyane ka sehlahisoa, amohela ho ikopanya le rona 'me re tla u fa sehlahisoa se loketseng ka ho fetisisa le tšebeletso e ntle ka ho fetisisa!