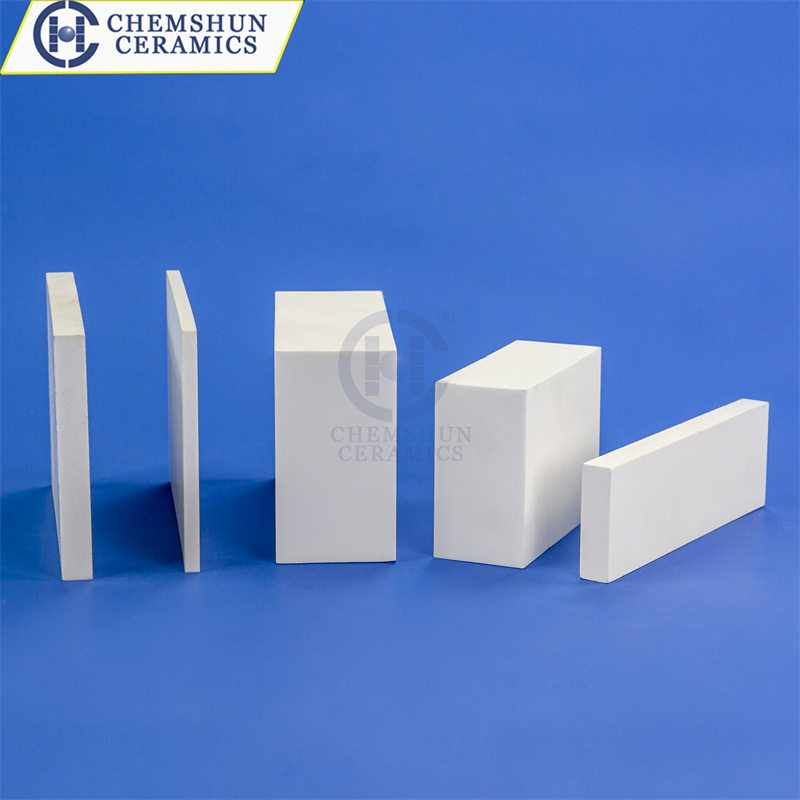

Apara Lithaele tsa Ceramic tse sa Tletseng

Tlhaloso

Lithaele tsa Chemshun tsa ceramic li thusa basebelisi ho fokotsa nako ea bona ea ho fokotsa nako le ho ntlafatsa tlhahiso ea bona Chemshun e ka fa bareki lithaelese tse nepahetseng ka ho fetesisa ho amohela tlhokahalo ea ts'ireletso ea lisebelisoa tse nang le lesela la ceramic: lithaele tse hlakileng, lithaele tse chesehang, lithaele tsa trapezoidal, lithaele tse kobehileng le tse notlellang, le lithaele tsa boenjiniere. ka li-geometri tse khethehileng, likotoana tse ling tsa mosaic ke lisebelisoa tse ntle ka ho fetisisa tsa abrasion bakeng sa vulcanized ka pampiri ea rabara.Mona re kenyelletsa lithaele tsa chemshun alumina ceramic bakeng sa Hopper, chute, sefefo, lipeipi tsa lipeipi joalo-joalo bakeng sa tlhaiso-leseling ea hau.

Alumina e roala letsatsi la theknoloji la liner

| S.No. | Litšobotsi | Yuniti | Chemshun 92 | Chemshun 92 | Chemshun 95 | Chemshun ZTA |

| 1 | Litaba tsa Alumina | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 3 | Botenya | g/cc | ≥3.60 | ≥3.60 | = 3.65 | ≥4.2 |

| 4 | Mmala | - | Bosoeu | Bosoeu | Bosoeu | Bosoeu |

| 5 | Ho Monyeha ha Metsi | % | <0.01 | <0.01 | 0 | 0 |

| 6 | Flexural Matla | Mpa | 270 | 300 | 320 | 680 |

| 7 | Moh's Density | Kereiti | 9 | 9 | 9 | 9 |

| 8 | Rock Well Hardness | HRA | 80 | 85 | 87 | 90 |

| 9 | Vickers Hardness(HV5) | Kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 10 | Matla a Fracture(Mots) | MPa.m1/2 | 3-4 | 3-4 | 3-4 | 4-5 |

| 11 | Matla a hatellang | Mpa | 850 | 850 | 870 | 1500 |

| 12 | Thermal Expansion Coefficient(25-1000℃) | 1x10-6/℃ | 8 | 7.6 | 8.1 | 8.3 |

| 13 | Boholo ba mocheso oa ts'ebetso | ℃ | 1450 | 1450 | 1500 | 1500 |

Kopo ho Industries

| Indasteri | Sistimi ea lisebelisoa | Likarolo tsa lisebelisoa |

| Samente | Sistimi ea ho kopanya esale pele bakeng sa lejoe la mokoetla le senyehileng le mafura a tala | Chute, bunker, pulley lagging, discharge cone |

| Sistimi ea leloala e tala | Fepa chute, selikalikoe sa ho boloka, poleiti ea scraper, selikalikoe sa tiiso, pipeline, bucket guard, leholiotsoana, 'mele oa concentrator ea phofo, bunker | |

| Sisteme ea leloala la samente | Chute, bunker, fan vane wheel, fan casing, cyclone, circular duct, conveyer | |

| Sistimi ea leloala la bolo | 'Mele oa mochini o ntšang metsi le lebili la vane,' mele oa sekontiri sa phofo, phala ea mashala a pshatlehileng, kotopo ea moea o chesang | |

| Sintering system | Koba ea ho kena/ho ntša, poleiti ea boleng ba moea, leholiotsoana, chute, phala ea ho bokella lerole | |

| Sistimi ea kamora mocheso | Phaephe ea karohano le lebota | |

| Tšepe | Mokhoa oa ho fepa ka thepa e tala | Hopper, silo |

| Sistimi ea ho kopanya | Ho kopanya bunker, moqomo oa ho kopanya, disk e kopanyang, disk pelletizer | |

| Sintered material transport system | Hopper, silo | |

| Sistimi ea ho ntša le ho ntša molora | Phaephe ea ho tlosa, bend, y-piece | |

| Mokhoa oa ho pheha | Coke hopper | |

| Leloala la lebelo le mahareng | Khoune, li-buffles tsa karohano, phala e tsoang ka ntle, phala ea mashala a pshatlehileng, khoune ea mollo | |

| Leloala la bolo | Sehlopha, se arolang leholiotsoana, kobeha, khetla e ka hare ea sekontiri sa phofo | |

| Matla a futhumatsang | Mokhoa oa ho tšoara mashala | Mochini oa mabili a bakete, sekoti sa mashala, sefepi sa mashala, orifice |

| Sistimi ea leloala la bolo | Peipi ea karohano, setsoe le khoune, setsoe sa leloala la mashala le tube e otlolohileng. | |

| Leloala la lebelo le mahareng | 'mele oa leloala la mashala, li-buffle tsa karohano, khoune, lipeipi, setsoe | |

| Leloala la ho oa | Phaephe ea mashala a pshatlehileng le setsoe | |

| Sistimi ea ho tlosa | Phaephe ea Dedusting le setsoe | |

| Sistimi ea ho ntša molora | Sekhetla sa Fan duster, pipeline | |

| Boema-kepe | Tsamaiso ea thepa ea ho tsamaisa | Disk le hopper ea mochini oa mabili a bakete, sekoti sa sebaka sa phetisetso, hopper ea ho laolla, |

| Ho qhibilihisa | Tsamaiso ea thepa ea ho tsamaisa | Methara ea ho metha, coke hopper, chute ea skrine se thothomelang, belofo ea hlooho, Bene e bohareng, bin ea mohatla |

| Sistimi ea ho kopanya | batch hopper, mochini o kopanyang | |

| Tsamaiso ea ho chesa | Bakete ea molora, pompo ea calcine tube, hopper | |

| Sistimi ea ho tlosa | Phaephe ea Dedusting le setsoe | |

| Lik'hemik'hale | Tsamaiso ea thepa ea ho tsamaisa | Hopper, silo |

| Sistimi ea ho tlosa | Phaephe ea Dedusting le setsoe | |

| Lisebelisoa tsa ho sebetsa | Sesebelisoa sa Vibromill | |

| Mashala | Mokhoa oa ho tšoara mashala | Mochini oa mabili a bakete, sekoti sa mashala, sefepi sa mashala |

| Mokhoa oa ho hlatsoa mashala | Hydrocyclone | |

| Morafo | Tsamaiso ea thepa ea ho tsamaisa | Hopper, silo |

Tshebeletso

Re amohela litaelo tsa tloaelo.

Haeba u batla ho tseba haholoanyane ka sehlahisoa, ka kopo ikutloe u lokolohile ho ikopanya le rona 'me re tla u fa sehlahisoa se loketseng le tšebeletso e ntle ka ho fetisisa!