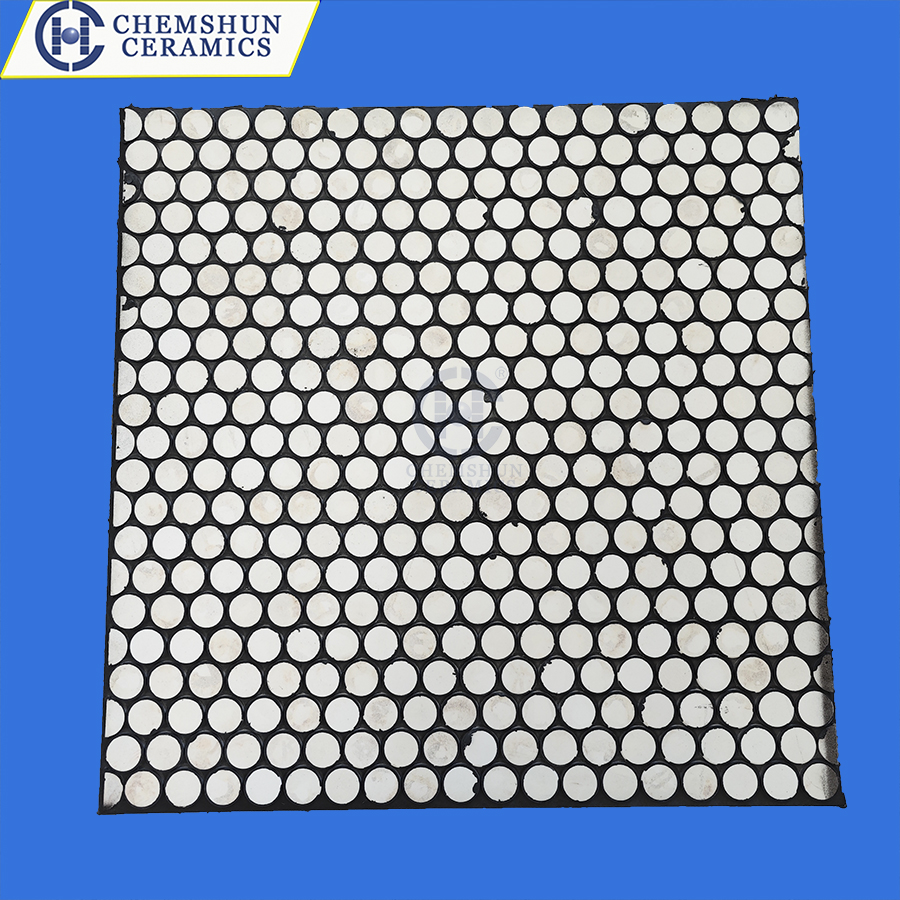

Alumina Cylinder e Hlakotsoe e le Lipoleiti tsa Rabara ea Ceramic

Likaroloana

1)Bothata bo phahameng.

2) Khahlano e phahameng ea abrasion.

3) Corrosion le khanyetso ea lik'hemik'hale.

4) Boima bo bobebe.

5) E ka vulcanized ka mefuta eohle ea phanele ea rabara kapa conveyor.

Kopo ho Industries

| Indasteri | Sistimi ea lisebelisoa | Likarolo tsa lisebelisoa |

| Samente | Sistimi ea ho kopanya esale pele bakeng sa lejoe la mokoetla le senyehileng le mafura a tala | Chute, bunker, pulley lagging, discharge cone |

| Sistimi ea leloala e tala | Fepa chute, selikalikoe sa ho boloka, poleiti ea scraper, selikalikoe sa tiiso, pipeline, bucket guard, leholiotsoana, 'mele oa concentrator ea phofo, bunker | |

| Sisteme ea leloala la samente | Chute, bunker, fan vane wheel, fan casing, cyclone, circular duct, conveyer | |

| Sistimi ea leloala la bolo | 'Mele oa mochini o ntšang metsi le lebili la vane,' mele oa sekontiri sa phofo, phala ea mashala a pshatlehileng, kotopo ea moea o chesang | |

| Sintering system | Koba ea ho kena/ho ntša, poleiti ea boleng ba moea, leholiotsoana, chute, phala ea ho bokella lerole | |

| Sistimi ea kamora mocheso | Phaephe ea karohano le lebota | |

| Tšepe | Mokhoa oa ho fepa ka thepa e tala | Hopper, silo |

| Sistimi ea ho kopanya | Ho kopanya bunker, moqomo oa ho kopanya, disk e kopanyang, disk pelletizer | |

| Sintered material transport system | Hopper, silo | |

| Sistimi ea ho ntša le ho ntša molora | Phaephe ea ho tlosa, bend, y-piece | |

| Mokhoa oa ho pheha | Coke hopper | |

| Leloala la lebelo le mahareng | Khoune, li-buffles tsa karohano, phala e tsoang ka ntle, phala ea mashala a pshatlehileng, khoune ea mollo | |

| Leloala la bolo | Sehlopha, se arolang leholiotsoana, kobeha, khetla e ka hare ea sekontiri sa phofo | |

| Matla a futhumatsang | Mokhoa oa ho tšoara mashala | Mochini oa mabili a bakete, sekoti sa mashala, sefepi sa mashala, orifice |

| Sistimi ea leloala la bolo | Peipi ea karohano, setsoe le khoune, setsoe sa leloala la mashala le tube e otlolohileng. | |

| Leloala la lebelo le mahareng | 'mele oa leloala la mashala, li-buffle tsa karohano, khoune, lipeipi, setsoe | |

| Leloala la ho oa | Phaephe ea mashala a pshatlehileng le setsoe | |

| Sistimi ea ho tlosa | Phaephe ea Dedusting le setsoe | |

| Sistimi ea ho ntša molora | Sekhetla sa Fan duster, pipeline | |

| Boema-kepe | Tsamaiso ea thepa ea ho tsamaisa | Disk le hopper ea mochini oa mabili a bakete, sekoti sa sebaka sa phetisetso, hopper ea ho laolla, |

| Ho qhibilihisa | Tsamaiso ea thepa ea ho tsamaisa | Methara ea ho metha, coke hopper, chute ea skrine se thothomelang, belofo ea hlooho, Bene e bohareng, bin ea mohatla |

| Sistimi ea ho kopanya | batch hopper, mochini o kopanyang | |

| Tsamaiso ea ho chesa | Bakete ea molora, pompo ea calcine tube, hopper | |

| Sistimi ea ho tlosa | Phaephe ea Dedusting le setsoe | |

| Lik'hemik'hale | Tsamaiso ea thepa ea ho tsamaisa | Hopper, silo |

| Sistimi ea ho tlosa | Phaephe ea Dedusting le setsoe | |

| Lisebelisoa tsa ho sebetsa | Sesebelisoa sa Vibromill | |

| Mashala | Mokhoa oa ho tšoara mashala | Mochini oa mabili a bakete, sekoti sa mashala, sefepi sa mashala |

| Mokhoa oa ho hlatsoa mashala | Hydrocyclone | |

| Morafo | Tsamaiso ea thepa ea ho tsamaisa | Hopper, silo |

Leqephe la Boitsebiso ba Teknoloji

| S.No. | Litšobotsi | Yuniti | CHEMSHUN 92 I | CHEMSHUN92 II | CHEMSHUN 95 | CHEMSHUN ZTA |

| 1 | Litaba tsa Alumina | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 2 | Botenya | g/cc | ≥3.60 | ≥3.60 | >3.65 | ≥4.2 |

| 3 | Mmala | - | Bosoeu | Bosoeu | Bosoeu | Bosoeu |

| 4 | Ho Monyeha ha Metsi | % | <0.01 | <0.01 | 0 | 0 |

| 5 | Flexural Matla | Mpa | 270 | 300 | 320 | 680 |

| 6 | Moh's Density | Kereiti | 9 | 9 | 9 | 9 |

| 7 | Rock Well Hardness | HRA | 80 | 85 | 87 | 90 |

| 8 | Vickers Hardness(HV5) | Kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 9 | Matla a Fracture (Mots) | MPa.m1/2 | 1000 | 3-4 | 3-4 | 4-5 |

| 10 | Matla a hatellang | Mpa | 850 | 850 | 870 | 1500 |

| 11 | Mocheso oa Katoloso ea Mocheso (25-1000ºC) | 1×10-6/ºC | 8 | 7.6 | 8.1 | 8.3 |

| 12 | Boholo ba mocheso oa ts'ebetso | ºC | 1450 | 1450 | 1500 | 1500 |

Chemshun Ceramic Melemo

1)Sehlopha sa litsebi sa botekgeniki ho lefella meralo ea CAD.

2) Sehlopha sa profeshenale sa ho kenya chelete ho lefella tšebeletso ea ho kenya.

3) Ts'ebetso e thehiloeng hantle ho latela maemo a machabeng.

4) Amohela lithaele tse tloaelehileng le tse entsoeng pele.

Li-tag tsa Sehlahisoa

Ngola molaetsa wa hao mona mme o re romele wona