Lesale la Ceramic la Zirconia

Tlhaloso ea Sehlahisoa:

Khampani e nka theknoloji e tsoetseng pele ea lefats'e le ts'ebetso e le sepheo sa ho nchafatsa, e nka lisebelisoa tsa setsebi le lisebelisoa tsa tlhahlobo, e laola ka thata boleng ba sehlahisoa, 'me e fana ka Y-ZR, A-ZR, FZTA le silicon carbide le matla a mang a phahameng, ho hanyetsa ho roala, ho hanyetsa kutu, mocheso o phahameng oa ho hanyetsa likarolo tsa ceramic ho limmaraka tsa malapeng le tsa linaheng tse ling. Har'a tsona, thepa ea ceramic ea A-ZR e sebelisoa haholo libakeng tse sa tšoaneng tsa indasteri ka ts'ebetso ea eona e ntle ea litšenyehelo le boleng bo ka tšeptjoang.

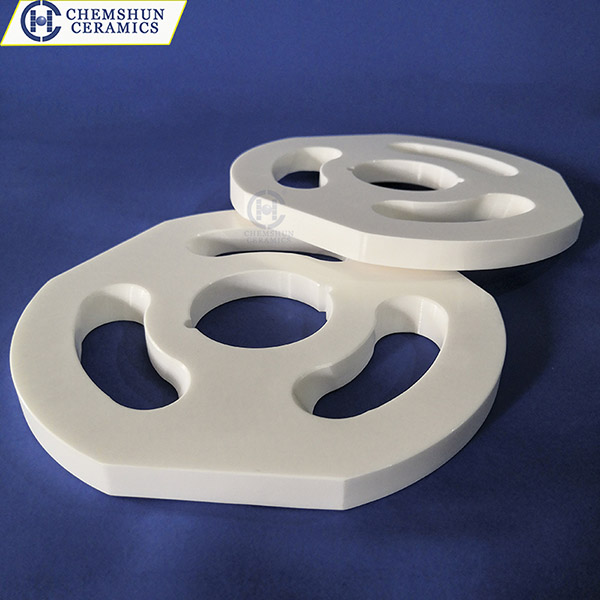

Ka bokhoni ba rona ba tlhahiso ka mechini e nepahetseng ea ho sila, re khona ho fana ka likarolo tse ngata tse fapaneng tse nepahetseng tsa zirconia tsa ceramic ho fihlela litlhoko tse phahameng tsa kopano ea bareki.

Likarolo tsa mantlha:

1) Matla a phahameng;

2) Corrosion manganga;

3) Khanyetso e phahameng ea ho roala, boits'oaro bo botle.

Libaka tsa kopo:

E loketse li-valve core, hlobo, sesebelisoa sa ho itšeha, ho beha, shaft, reng ea ho tiisa, liner, joalo-joalo.

Papiso ea likarolo tse felletseng tsa ts'ebetso ea lisebelisoa tse fapaneng tsa zirconia ceramic:

| A-ZR | Y-ZR | FZTA | |

| Litaba tsa ZrO2 | 90% | 94.5% | 40% |

| Boima ba g/cm³ | >5.9 | > 6.0 | >4.8 |

| Ho thatafala (HRA) | >89 | >89 | >89 |

| Bending Strength (MPa) | >1100 | >1000 | > 600 |

| Modulus of Elasticity (GPA) | 230 | 200 | 180 |

| Coefficient of Thermal Conductivity (W/Wm.k) | 4 | 3 | 6 |

| Bothata ba Fracture (MPa.m½) | 10 | 8 | 3.5 |

| Khanyetso ea Corrosion | A+ | A | A+ |

| Boemo bo Phahameng ba Mocheso oa ho Roala Resistance | A+ | A | A |

| Ho hanyetsa ho Apara ka Mocheso o Tloaelehileng | A+ | A+ | A |

| Ho hanyetsa Mokhathala | A+ | A | A+ |