Likotoana tsa Alumina Ceramic Lining

Melemo

1) Ho hanyetsa ka mokhoa o babatsehang oa abrasion;

2) Tšusumetso e ntle ea ho hanyetsa;

3) Excellent hardness;

4) Ho hanyetsa kutu e ntle haholo (hanela alkaline e matla, slag e matla ea acid le lisebelisoa tse nang le mokelikeli);

5) Ho hanyetsa mocheso o babatsehang (ho fihlela ho 1500 ℃);

6) Sebaka se boreleli se ka fokotsa sekhahla le khohlano ea coefficient ho lelefatsa bophelo ba sesebelisoa sa ho sebetsa;

7) Boima bo tlase bo ka fokotsa boima ba lisebelisoa tse kentsoeng le ho ntlafatsa katleho ea lisebelisoa.

Lintlha tsa tekheniki

| Thepa | Yuniti | Chemshun 92 | Chemshun 95 |

| Al2O3 | % | 92 | 95 |

| Botenya | g/cm3 | 3.6 | 3.65 |

| Bothata ba Moh | Kereiti | 9 | 9 |

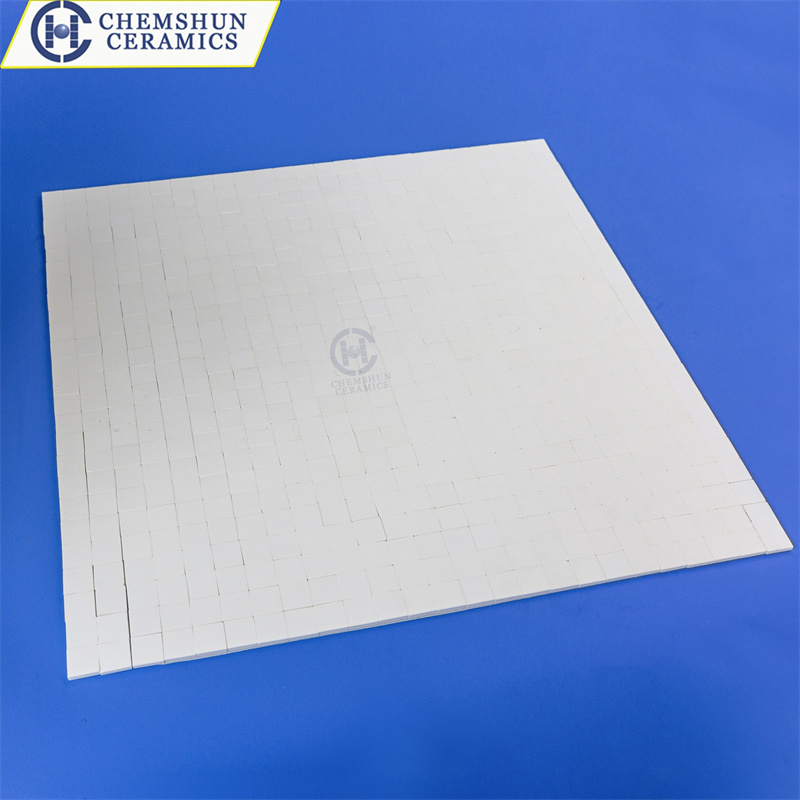

| Lihlahisoa | Boholo ka mm (L*W*T) kapa (S*T) | ||

| Tile ea Ceramic Square | 10*10*2~10, 17.5*17.5*2~15, 20*20*2~10, 33*33*5~25, joalo-joalo. | ||

| Ceramic Hexagonal tile | 6*3~6, 11*3~25, 12*3~25, 19*3~25, joalo-joalo. | ||

| Hex/Square Tile Mat | 32*32*32, 40*40*40, joalo-joalo. | ||

| Boitsebiso ba Mats | Pampiri, Mesh ea Nylon, Lesela la Acetate, joalo-joalo. | ||

Kopo

| Indasteri ea Kopo e tsoang Chemshun | ||

| Indasteri | Sistimi ea lisebelisoa | Likarolo tsa lisebelisoa |

| Samente | Sistimi ea ho kopanya esale pele bakeng sa lejoe la mokoetla le senyehileng le mafura a tala | Chute, Bunker, Pulley lagging, discharge cone |

| Sistimi ea leloala e tala | Fepa chute, Ring e bolokang,Scraper plate,Seal ring,Pipeline,Bucket guard,Leholiotsoana,Powder concentrator body,Bunker | |

| Sisteme ea leloala la samente | Chute,Bunker,Fan vane wheel,Fan casing,Cyclone,Circular duct,Conveyer | |

| Sistimi ea leloala la bolo | 'Mele oa mochini o ntšang metsi le lebili la vane,'Mele oa sekontiri sa phofo,Peipi ea mashala a silafalitsoeng,Mopopo oa moea o chesang | |

| Sintering system | Inlet/Outlet bend,Wind value plate,Leholiotsoana,Chute,peipi ea pokello ea lerōle | |

| Sistimi ea kamora mocheso | Phaephe ea karohano le lebota | |

| Tšepe | Mokhoa oa ho fepa ka thepa e tala | Hopper, Silo |

| Sistimi ea ho kopanya | Bunker e kopanyang, moqomo oa ho kopanya, disk e kopanyang, disk pelletizer | |

| Sintered material transport system | Hopper, Silo | |

| Sistimi ea ho ntša le ho ntša molora | Phaephe ea ho tlosa, Bend, Y-piece | |

| Mokhoa oa ho pheha | Coke hopper | |

| Leloala la lebelo le mahareng | Khoune, Li-buffles tsa karohano, Peipi ea kantle,Peipi ea mashala a hlabositsoeng, Khoune e tukang | |

| Leloala la bolo | Sehlopha, Searohanyi sa Leholiotsoana, Koba,Sekhetla sa ka hare sa Powder concentrator | |

| Matla a futhumatsang | Mokhoa oa ho tšoara mashala | Mochini oa mabili a bakete, Sekoti sa Mashala,Sefepi sa Mashala,Orifice |

| Sistimi ea leloala la bolo | Peipi ea Separator, setsoe le khoune,Setsoe sa leloala la mashala le tube e otlolohileng | |

| Leloala la lebelo le mahareng | 'Mele oa leloala la mashala, Li-buffle tsa karohano, Khoune,Pipeline,Setsoe | |

| Leloala la ho oa | Pipeline ea mashala a pshatlehileng le Elbow | |

| Sistimi ea ho tlosa | Pipeline ea Dedusting le Elbow | |

| Sistimi ea ho ntša molora | Sekhetla sa Fan duster, Pipeline | |

| Boema-kepe | Tsamaiso ea thepa ea ho tsamaisa | Disk le hopper ea mochini oa libakete,Sehopa sa Transfer point,Hopper ea Unloader, |

| Ho qhibilihisa | Tsamaiso ea thepa ea ho tsamaisa | Hopper ea ho metha,Coke hopper,Chute ea skrine se thothomelang,Belofo ea hlooho,Moqo o mahareng,Mohatla |

| Sistimi ea ho kopanya | Batch hopper, mochini o kopanyang | |

| Tsamaiso ea ho chesa | Bakete ea molora, pompo ea calcine, Hopper | |

| Sistimi ea ho tlosa | Pipeline ea Dedusting le Elbow | |

| Lik'hemik'hale | Tsamaiso ea thepa ea ho tsamaisa | Hopper, Silo |

| Sistimi ea ho tlosa | Pipeline ea Dedusting le Elbow | |

| Lisebelisoa tsa ho sebetsa | Sesebelisoa sa Vibromill | |

| Mashala | Mokhoa oa ho tšoara mashala | Mochini oa mabili a bakete, Sekoti sa Mashala,Sefepi sa Mashala,Silo |

| Mokhoa oa ho hlatsoa mashala | Hydrocyclone | |

| Morafo | Tsamaiso ea thepa ea ho tsamaisa | Hopper, Silo |

Tshebeletso

Re amohela litaelo tsa tloaelo.

Haeba u batla ho tseba haholoanyane ka sehlahisoa, ka kopo ikutloe u lokolohile ho ikopanya le rona 'me re tla u fa sehlahisoa se loketseng le tšebeletso e ntle ka ho fetisisa!