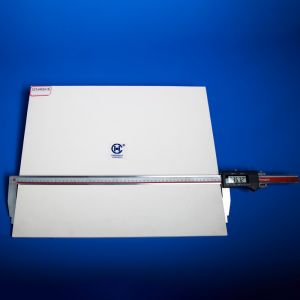

99.7% Alumina Ceramic Baseboard

Kopo

Joalo ka Alumina Substrate bakeng sa phanele ea LCD (PFD, PDF, TFT…) lisebelisoa tsa tlhahiso.

Bakeng sa indasteri e kholo ea LCD khalase ea substrate manipulator.

Bakeng sa lisebelisoa tsa lithography.

Sebopeho

Bohloeki bo phahameng le ho tšoarella ha lik'hemik'hale

Matla a Mechane a Phahameng le ho Thatafala

High Corrosion Resistance

High Voltage Resistance

Mocheso o Holimo Ho fihla ho 1700ºC

Ts'ebetso e Feteletseng ea Abrasion Resistance

Ts'ebetso e Ntle ea Insulation

Boholo bo boholo

Boholo bo boholo

| Lebitso la sehlahisoa | Chemshun boholo bo boholo bo hloekileng bo phahameng Alumina ceramic substrate ceramic panel |

| Lintho tse bonahalang | 99.7% alumina |

| Boholo bo Tloaelehileng | 1200x500x20, 1400x900x30, boholo bo ikhethileng bo amoheloa. |

| Mmala | Lenaka la tlou |

| Kopo | LCD panel (PFD, PDF, TFT ...) lisebelisoa tsa tlhahiso. |

| Min.Order | 1Pic |

Boitsebiso ba lik'hemik'hale / 'mele

| Yuniti | 99.7 Alumina Ceramics | ||

| Kakaretso Thepa | Likahare tsa Al2O3 | wt% | 99.7-99.9 |

| Botenya | gm/cc | 3.94-3,97 | |

| Mmala | - | Lenaka la tlou | |

| Ho monya metsi | % | 0 | |

| Thepa ea Mechini | Flexural Strength(MOR) 20 ºC | Mpa(psix10^3) | 440-550 |

| Elastic Modulus 20ºC | GPA (psix10^6) | 375 | |

| Vickers Hardness | Gpa(kg/mm2) R45N | >>=17 | |

| Matla a Kobehang | GPA | 390 | |

| Matla a Tensile 25ºC | MPa(psix10^3) | 248 | |

| Fracture Toughness (KI c) | Mpa* m^1/2 | 4-5 | |

| Thermal Properties | Thermal conductivity(20ºC) | W/mk | 30 |

| Coefficient of Thermal extension(25-1000ºC) | 1x 10^-6/ºC | 7.6 | |

| Thermal Shock Resistance | ºC | 200 | |

| Boholo ba mocheso oa tšebeliso | ºC | 1700 | |

| Thepa ea Motlakase | Matla a Dielectric (1MHz) | ac-kv/mm(ac v/mil) | 8.7 |

| Dielectric Constant(1 MHz) | 25ºC | 9.7 | |

| Ho hanyetsa Molumo | ohm-cm (25ºC) | >10^14 | |

| ohm-cm (500ºC) | 2×10^12 | ||

| ohm-cm (1000ºC) | 2×10^7 |

Tshebeletso

Re amohela litaelo tsa tloaelo.

Haeba u batla ho tseba haholoanyane ka sehlahisoa, ka kopo ikutloe u lokolohile ho ikopanya le rona 'me re tla u fa sehlahisoa se loketseng le tšebeletso e ntle ka ho fetisisa!

Li-tag tsa Sehlahisoa

Ngola molaetsa wa hao mona mme o re romele wona