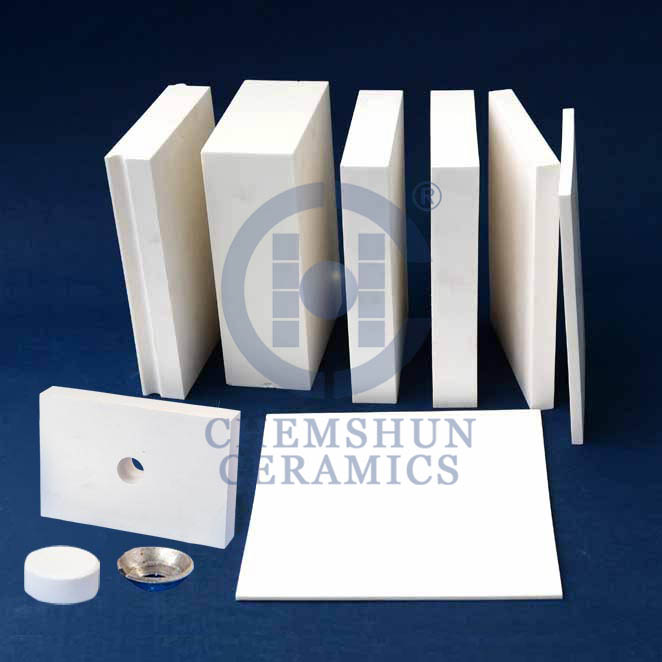

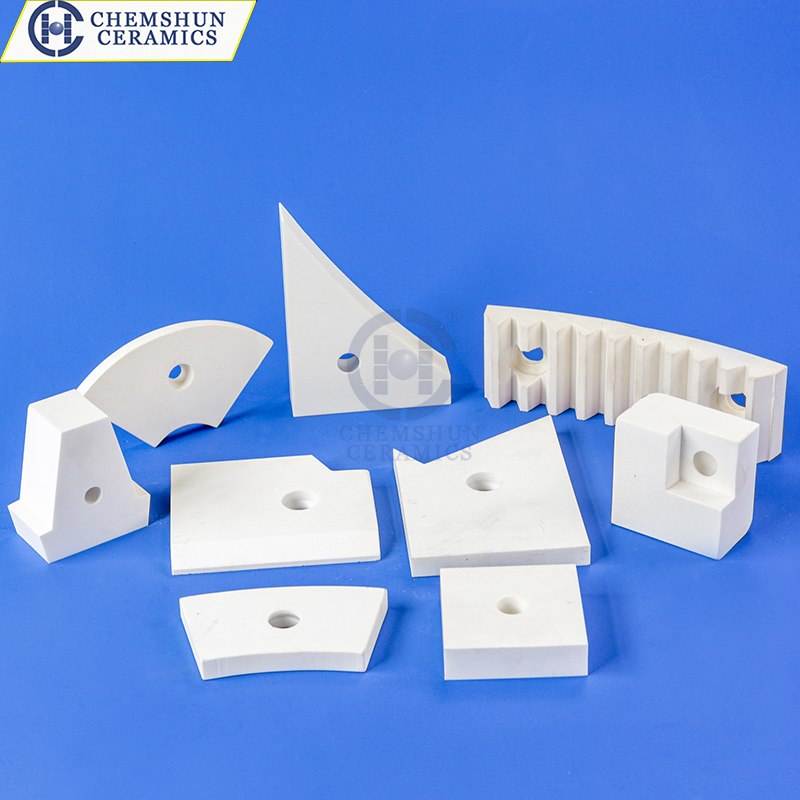

Lesela la ceramic le sa keneleng ho roalatile, eo hape e tsejoang e le: lesela la ceramic le sa sebetsengtile, lesela le phahameng la aluminium, lesela le sa senyehengtile, lesela la alumina, ceramic ceramic tile lesela le manganga liphaephe.

Likarolo: Ka ho hanyetsa ts'ebetso, ho hanyetsa ts'ebetso, ho hanyetsa kutu, ho hanyetsa mocheso o phahameng, kaho e bonolo le litšobotsi tse ling, ke matla a motlakase, metallurgy, mashala, peterole, samente, lik'hemik'hale, mechine le lisebelisoa tse ling (tse kang molora oa molora, phofo ea mashala, e ntle. phofo ea ore, mehatla, samente, joalo-joalo) e tsamaisang thepa e sa sebetsaneng le thepa ea boleng bo holimo, ka mocheso o phahameng oa kutu, mocheso o phahameng kapa mocheso o phahameng oa mocheso tlas'a ts'ebeliso e sireletsehileng le e tšepahalang, bophelo ba eona bo phahame ka makhetlo a leshome ho isa ho a mashome a mabeli ho feta. ea lejoe le entsoeng ka tšepe, tšepe e sa sebetseng ea alloy cast, polasetiki ea tšepe, rabara ea tšepe le lisebelisoa tse ling.

Indasteri ea likopo:

Indasteri ea tšepe

Sistimi ea phepelo: libakete tsa turbine disc, hopper, bin, poleiti ea seaparo sa mochini oa lebanta, bakete ea tee ea trolley, ho amohela hopper.

Sistimi ea ho kopanya: moqomo oa ho kopanya, cylinder ea mantlha ea ho kopanya, silinda ea bobeli ea ho kopanya, disc e kopanyang, ho kopanya moqomo, ho etsa disc ea bolo..

Sintering system: ho thothomela skrineng sa beneficiation hopper, chute ea lipalangoang tse tala, pokello ea lerōle la leholiotsoana le liphaephe, mochini o tsamaisang thepa..

Indasteri ea samente

Sistimi ea ho senya lejoe la mokoetla le sistimi e tala ea prehomogenization ea mafura: chute, hopper, rolara ea lebanta.

Sistimi e tala ea ho sila: lehare la tataiso, khoune ea karohano, ho sila ho ea ho leholiotsoana bobbin, moqomo oa leholiotsoana, leloala la mafura (tšepe ea bolo), khetla ea karohano, khoune e ka hare, phala ea mashala e pshatlehileng..

Fuel mill (steel ball mill): khetla e arolang, khoune e ka hare, phala ea mashala e thuntsoeng, phala ea mashala.

Indasteri ea boema-kepe

Berth e tsitsitseng, enjene ea libakete e tsitsitseng, seteishene sa phetisetso ea lebanta le tsamaisang thepa e tsitsitseng, sekepe sa ho laolla thepa.

Indasteri ea ho qhibilihisa

Sistimi ea phepo: chute ea hlooho, silo (silo e bohareng, silo ea mohatla), nkho ea lisebelisoa tse sisinyehang, bakete ea coke, bakete ea metering.

Batching system: batching bakete, motsoako oa mantlha (oa bobeli)..

Sistimi ea ho halika: tube e le 'ngoe ea pompo ea calcine, sekoti se benyang, sekoti sa molora, sekoti sa bin se mahareng..

Indasteri ea lik'hemik'hale

Sistimi ea ho fepa: hopper, bin.

Sistimi ea ho tlosa lerōle: phala ea ho tlosa lerōle, setsoe, khetla ea fan le impeller, leholiotsoana.

Indasteri ea mashala

Sistimi ea lipalangoang tsa mashala: chute, hopper, bin.

Sistimi ea ho hlatsoa mashala: leholiotsoana la khatello, ha ho na khatello ea lihlahisoa tse tharo tse matla tsa leholiotsoana, ha ho khatello ea lihlahisoa tse 'ne tsa leholiotsoana la media, sehlopha sa leholiotsoana se concentrated.

Sistimi ea phepelo: phala, setsoe, phala, hopper, bin, boema-kepe ba kabo.

Indasteri ea merafo

Sistimi ea ho fepa: bin ea hopper.

Ho kenya: e arotsoe ka welding le sekhomaretsi tse peli, ho ea ka tikoloho ea kaho.

Nako ea poso: Dec-21-2022